What is Smart warehouse management solution ?

Brief introduction of Smart warehouse management

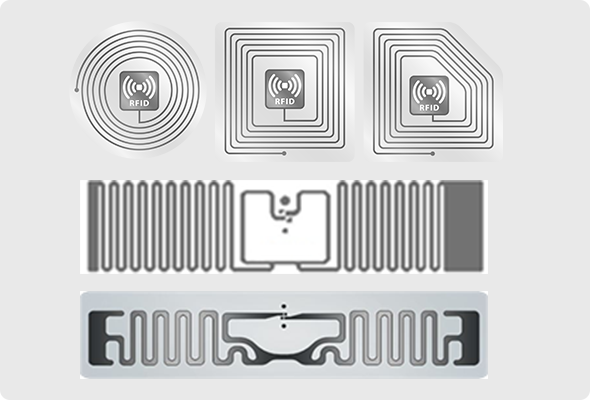

At present, RFID technology is bringing a tremendous change to the supply chain field, to identify the advantages of barcodes that are far away, fast, not easily damaged, and large in size, simplify the complicated workflow, and effectively improve the efficiency and transparency of the supply chain. Cirtek’s RFID-based warehouse management system introduces RFID technology into the existing warehouse management, and automates the data of various operations such as warehouse arrival inspection, warehousing, transfer, warehouse shifting, inventory counting, etc. Collection, to ensure the speed and accuracy of data input in all aspects of warehouse management, to ensure that the enterprise timely and accurately grasps the real data of the inventory, to reasonably maintain and control the enterprise inventory.

Through scientific coding, it is also easy to manage the batch and shelf life of items. By using the system’s storage location management function, you can timely grasp the current location of all inventory materials, which is conducive to improving the efficiency of warehouse management.

RFID Smart Warehouse Management Solution-System Features

Real-time data

In the production process, it is very important that the production line feed back information in a timely and accurate manner. Before the RFID system, the factory could only manually record faults and scraps while producing, and make overall statistics after the production was completed to estimate the process efficiency, which was time-consuming, laborious, and sometimes not very accurate. Now, as long as RFID reading equipment is installed on various equipment and processes in the production line, and RFID electronic tags that can be read and written repeatedly are placed on the products or trays. In this way, when the product passes through these nodes, the RFID reading device can read the information in the label on the product or tray, and feed back this information to the back-end management system in real time. The administrator can easily and timely understand the situation of the production line .

Process standard automation

The RFID system can provide a constantly updated real-time data stream, which is complementary to the manufacturing management system. The information provided by the RFID can be used to ensure the correct use of machinery, equipment, tools and parts, etc., so as to realize automatic data transmission and reduce downtime. Furthermore, when raw materials, parts and assemblies pass through the production line, real-time control, modification or even reorganization of the production process can be performed to ensure the reliability and high quality of production.

Quality tracking and traceability

On a production line that implements an RFID system, product quality is generally detected by some test processes distributed in several places. At the end of production or before product acceptance, all previously collected data must be used to verify its quality. Using RFID electronic tags can easily do this, because the quality data obtained during the entire production process has been uploaded directly to the database as the product is produced, which is convenient for early detection of problems to reduce waste and improve quality.

RFID Smart Warehouse Management Solution Introduction

At present, RFID technology is bringing a tremendous change to the supply chain field, to identify the advantages of barcodes that are far away, fast, not easily damaged, and large in size, simplify the complicated workflow, and effectively improve the efficiency and transparency of the supply chain. Changda’s RFID-based warehouse management system introduces RFID technology into the existing warehouse management, and automates the data of various operations such as warehouse arrival inspection, warehousing, warehousing, transfer, warehouse shifting, inventory counting, etc. Collection, to ensure the speed and accuracy of data input in all aspects of warehouse management, to ensure that the enterprise timely and accurately grasps the real data of the inventory, to reasonably maintain and control the enterprise inventory.

Through scientific coding, it is also easy to manage the batch and shelf life of items. By using the system’s storage location management function, you can timely grasp the current location of all inventory materials, which is conducive to improving the efficiency of warehouse management.

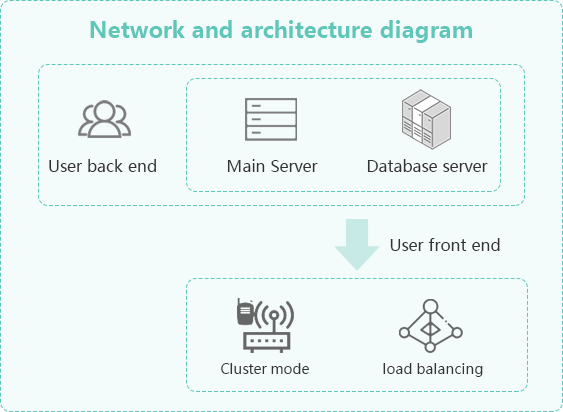

1. The framework

The entire system adopts a B / S / S three-tier architecture,consisting of a client, an application server, and a database server (three servers can be configured individually or combined). Both the application server and the database server adopt a cluster mode to support load balancing , To ensure the scalability and stability of the system.

Advantages

Fast recognition

As soon as the tag enters the RFID field, the reader can immediately read the information in it; using RFID anti-collision technology and a fixed reader, it can read dozens or hundreds of tags in an instant, greatly improving scanning efficiency and reducing labor costs.

Automatic In/Out counting

Using active electronic tags, the effective identification distance can reach more than 30 meters. It effectively solves the problem that the barcode storage in the past must manually scan the barcode, realizes automatic entry and exit, and greatly improves the storage labor cost and the efficiency of the forklift.

Penetrating and unobstructed reading

RFID can penetrate non-metallic and non-transparent materials such as paper, wood, and plastic for penetrating communication without the need for a light source. Provide a better scanning experience, can quickly tally, find goods, inventory, is the warehouse management accelerator.

Large data capacity

RFID is large MegaBytes storage. With the development of chip memory , it makes the capacity of memory larger and the capacity of the tags to will increase accordingly.

Long workable life, withstand in harsh condition

The wireless connection of RFID makes it can work stable under any condition.

Tag data can be changed

The content of RFID tags can be changed, and RFID tags can be reused to get rid of the situation that traditional barcode tags can only be used once, which can effectively reduce the cost of consumables for enterprises.

Better security

Transfer the product data from the central computer to the tag to provide security for the system, and use encryption to protect the data in the RFID tag to ensure that the data is not illegally read.

Small size and diversified shapes

RFID does not need to match the fixed size and printing quality of paper for reading accuracy. It is more suitable for the development of miniaturization and various forms to facilitate embedding or attachment to products of different shapes and types.

Advantages

Fast recognition

As soon as the tag enters the RFID field, the reader can immediately read the information in it; using RFID anti-collision technology and a fixed reader, it can read dozens or hundreds of tags in an instant, greatly improving scanning efficiency and reducing labor costs.

Automatic In/Out counting

Using active electronic tags, the effective identification distance can reach more than 30 meters. It effectively solves the problem that the barcode storage in the past must manually scan the barcode, realizes automatic entry and exit, and greatly improves the storage labor cost and the efficiency of the forklift.

Penetrating and unobstructed reading

RFID can penetrate non-metallic and non-transparent materials such as paper, wood, and plastic for penetrating communication without the need for a light source. Provide a better scanning experience, can quickly tally, find goods, inventory, is the warehouse management accelerator.

Large data capacity

RFID is large MegaBytes storage. With the development of chip memory , it makes the capacity of memory larger and the capacity of the tags to will increase accordingly.

Long workable life, withstand in harsh condition

The wireless connection of RFID makes it can work stable under any condition.

Tag data can be changed

The content of RFID tags can be changed, and RFID tags can be reused to get rid of the situation that traditional barcode tags can only be used once, which can effectively reduce the cost of consumables for enterprises.

Better security

Transfer the product data from the central computer to the tag to provide security for the system, and use encryption to protect the data in the RFID tag to ensure that the data is not illegally read.

Small size and diversified shapes

RFID does not need to match the fixed size and printing quality of paper for reading accuracy. It is more suitable for the development of miniaturization and various forms to facilitate embedding or attachment to products of different shapes and types.

The value of the program

Reduce labor

Labor can be reduced by 20-30%

Product visualization

Labor can reduce 20-30% and 99% of warehouse product visualization, reducing the risk of missing goods

Reduce labor

Improved supply chain management reduces working hours by 20-25%

Improve accuracy

Inventory availability increased by 5% ~ 10%, improving the accuracy and reliability of warehousing

Improve efficiency

Improve the throughput of warehouse products, efficient and accurate data collection, and provide operational efficiency

Minimize Error

Automatically collect data in and out of the warehouse to reduce human error

Cost reduction

The site management fee is reduced by 30%, the damage rate and the sales of expired goods can be reduced by 20%, and the cost of warehousing and logistics is reduced

![]()

Cirtek Intelligent IOT (Shenzhen) Co., Ltd.

Phone:0755-8891 0613

Email:info@cirteklink.com

Address:Room C, Unit B1, 3/F, Block AB, Tianxiang Bulding, Tian An Cyber Park, Tairan 5th Road, Futian District, Shenzhen City, Guangdong Province, China

Scan QR code to follow Learn more

Scan QR code to follow Learn more