What is a smart production solution?

Interpretation of intelligent production

Smart production refers to the integration of advanced production processes, systems, and models in which design and data have the functions of automatic information perception, automatic decision-making, and automatic execution. It is actually demonstrated in the deep integration of all important links in the production process with the new generation of information technology, such as the Internet of Things (IOT), big data, artificial intelligence, and cloud computing.

Smart production has four characteristics

The main contents include

At present, it is the general trend to establish a standard system for intelligent manufacturing, vigorously promote digital manufacturing, and develop core industrial software. The application and practice of traditional digital manufacturing, networked manufacturing, agile manufacturing and other manufacturing methods have an important supporting role for the development of intelligent manufacturing.

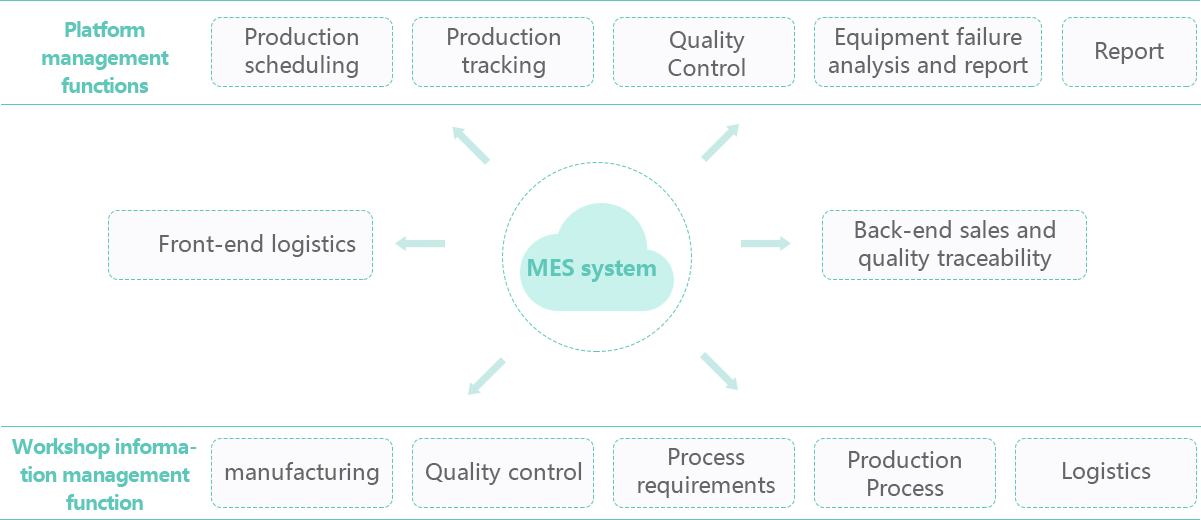

MES production system

The manufacturing industry implements the MES system, which can integrate management functions such as production scheduling, product tracking, quality management, equipment failure analysis and reporting, and reports on a unified platform. The use of a unified database and network connection can instantly provide manufacturing, quality control, and process Requirements, production processes, logistics distribution and other links provide production workshop information management functions. During the planning and deployment of the MES system, it is not only necessary to pay attention to the requirements for error-proof control in the production planning and workshop production process, but also to extend the MES system to the front-end logistics and back-end sales and quality traceability links. It is a comprehensive intelligent system that integrates software and human-machine interface equipment (PLC touch screen), PDA equipment, barcode and RFID tag readers, sensors, I / O, DCS, RFID, LED production kanban and other types of hardware. The group is composed of programs that share data, and the dedicated materials (PDA smart phones, LED production boards, barcode collectors, PLCs, sensors, I / O, DCS, RFID, PC and other hardware) placed on the production site are put online. The system of data collection, control and monitoring is implemented in the production process until the finished product is put into storage.

By controlling all plant resources including materials, warehouses, equipment, personnel, quality, processes, process instructions and facilities to improve manufacturing competitiveness, we provide a systematic integration of processes such as process orders and quality control on a unified platform , Document management, drawing issuance, production scheduling, equipment management, manufacturing logistics and other functional methods. So as to realize the real-time information system of the enterprise. The lean manufacturing system accepts the work order, BOM, process, supplier, inventory, manufacturing order and other information from the ERP system in real time. At the same time, the production method, personnel order, manufacturing order, etc. are issued to the control layer of personnel, equipment, etc. Production results, personnel feedback, equipment operation status and results, inventory status, quality status, etc. are dynamically fed back to the decision-making layer.

![]()

Cirtek Intelligent IOT (Shenzhen) Co., Ltd.

Phone:0755-8891 0613

Email:info@cirteklink.com

Address:Room C, Unit B1, 3/F, Block AB, Tianxiang Bulding, Tian An Cyber Park, Tairan 5th Road, Futian District, Shenzhen City, Guangdong Province, China

Scan QR code to follow Learn more

Scan QR code to follow Learn more